Latest News

-

Our visit to The Motorsport Engineering and Technology show

Exploring Innovation at the Motorsport Industry Association’s CTS Show at Silverstone On Tuesday 15th October, members of the Plyable team attended the Motorsport Industry Association’s (MIA) CTS – The Motorsport Engineering and Technology Show, hosted at the legendary Silverstone Circuit. As one of the UK’s premier motorsport venues, Silverstone provided the perfect backdrop for a…

-

This month we’ve welcomed our new Plyable Sales Director, Jamie Snudden.

We’re thrilled to welcome Jamie Snudden as the new Plyable Sales Director. Jamie brings a rare blend of technical expertise and commercial insight, making him the perfect fit to lead our growing sales team. With more than 15 years of experience in composite manufacturing across multiple sectors, Jamie offers a wealth of knowledge, passion, and…

-

Proud of our patented technology

We’ve just secured our 1st EU and UK patent for our Automated Molding feature! Plyable has just secured its first UK and EU patented technology for our Automated Molding technology feature, accessed through our Plyable manufacturing portal. This new level of protection will help drive innovation for our clients in the Aerospace, Automotive and Marine…

-

What We’re Looking Forward to at JEC World, Paris 2025!

The JEC World Tradeshow in Paris is the must-attend event for composites professionals. It’s where innovation meets real-world applications, and where the future of manufacturing takes shape. As we prepare to exhibit at the CompositesUK Pavilion this March, we’re not just excited about what’s happening on the show floor – we’re eager to see how…

-

How Plyable is Supporting Innovation in Electric Vehicles

The electric vehicle (EV) market is growing at an unprecedented rate, projected to reach over 30 million vehicles globally by 2030 [Deloitte]. As manufacturers strive to meet growing demand, they face challenges like reducing vehicle weight, improving efficiency, and achieving sustainability. Plyable is uniquely positioned to support the EV industry by providing advanced composite solutions…

-

Discover Plyable’s Vision for the Future of Composites Manufacturing

Last week, our CEO, Mark Runciman, sat down with Aerospace Xelerated to discuss the transformative role Plyable is playing in the composites and manufacturing industry. With a deep background in aerospace, automotive, and manufacturing innovation, Mark shared insights into how Plyable combines artificial intelligence and advanced technology to drive efficiency, precision, and agility in composite…

-

Welcome to 2025!

A Year of Growth, Innovation, and Collaboration As we step into 2025, we’re taking a moment to reflect on an incredible 2024. It’s been a year of collaboration, innovation, and progress at Plyable, and we couldn’t have done it without the support of our customers, suppliers, and partners. Here’s a look back at the highlights…

-

Plyable strengthens leadership team with appointment of Mark Runciman as CEO

Plyable, a global leader in composites manufacturing, announces Mark Runciman as its new Chief Executive Officer. Mark joins alongside Martin Oughton, who has played a pivotal role in guiding Plyable through its early development phase and building a one-of-a-kind- platform to provide automated tooling design, and instant quotations. Martin Oughton will continue to be an…

-

Plyable Wins Innovation in Composite Design Award at Composites UK 2024

Plyable has won the Innovation in Composite Design Award at the Composites UK Industry Awards 2024! Last night’s ceremony, held at the National Motorcycle Museum in Birmingham, was a chance to reflect on the achievements and advancements made within the UK composites sector in the last year. The Technology Behind the Award Traditional mold design…

-

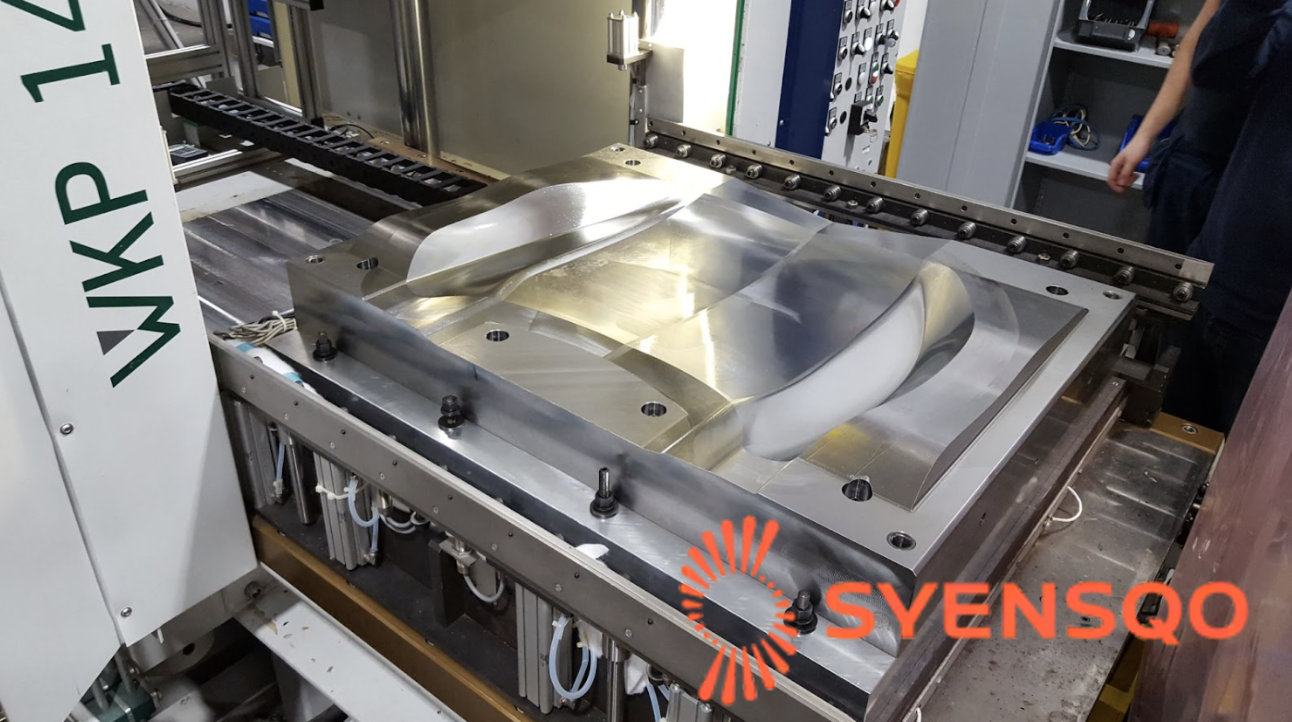

Project Spotlight: Accelerating R&D with Fast Turnaround Hot Press Tools

Dates: Nov 2020 – Present Day In a recent collaboration with leading materials supplier Syensqo, Plyable demonstrated its ability to deliver rapid and reliable tooling solutions, supporting advanced development projects focused on composite manufacturing. Client Name: Syensqo Challenge/Opportunity: Plyable began working with Syensqo’s Customer Engineering department in November 2020. As materials specialists, their focus is…