Category: News

-

How Plyable is Supporting Innovation in Electric Vehicles

The electric vehicle (EV) market is growing at an unprecedented rate, projected to reach over 30 million vehicles globally by 2030 [Deloitte]. As manufacturers strive to meet growing demand, they face challenges like reducing vehicle weight, improving efficiency, and achieving sustainability. Plyable is uniquely positioned to support the EV industry by providing advanced composite solutions…

-

Discover Plyable’s Vision for the Future of Composites Manufacturing

Last week, our CEO, Mark Runciman, sat down with Aerospace Xelerated to discuss the transformative role Plyable is playing in the composites and manufacturing industry. With a deep background in aerospace, automotive, and manufacturing innovation, Mark shared insights into how Plyable combines artificial intelligence and advanced technology to drive efficiency, precision, and agility in composite…

-

Welcome to 2025!

A Year of Growth, Innovation, and Collaboration As we step into 2025, we’re taking a moment to reflect on an incredible 2024. It’s been a year of collaboration, innovation, and progress at Plyable, and we couldn’t have done it without the support of our customers, suppliers, and partners. Here’s a look back at the highlights…

-

Plyable strengthens leadership team with appointment of Mark Runciman as CEO

Plyable, a global leader in composites manufacturing, announces Mark Runciman as its new Chief Executive Officer. Mark joins alongside Martin Oughton, who has played a pivotal role in guiding Plyable through its early development phase and building a one-of-a-kind- platform to provide automated tooling design, and instant quotations. Martin Oughton will continue to be an…

-

Plyable Wins Innovation in Composite Design Award at Composites UK 2024

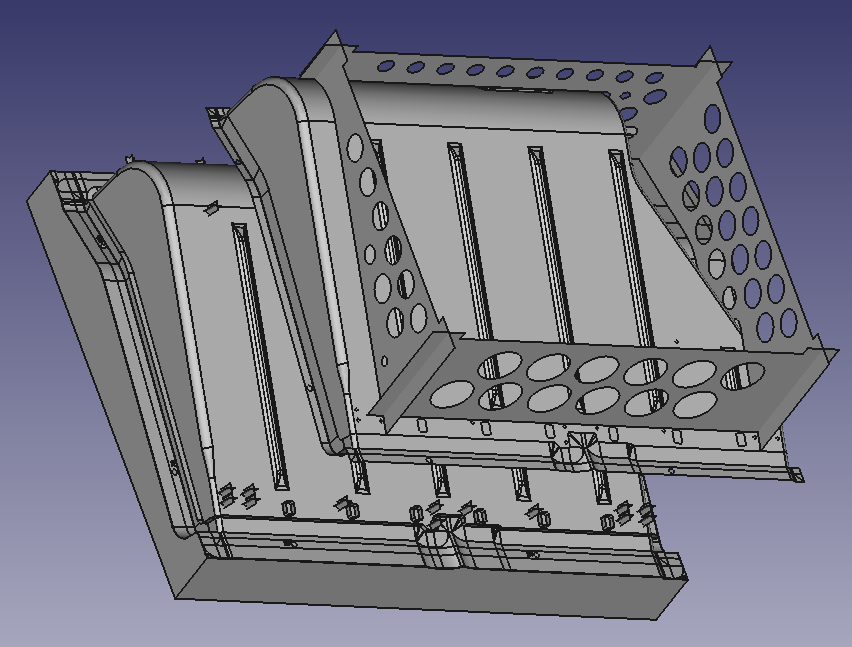

Plyable has won the Innovation in Composite Design Award at the Composites UK Industry Awards 2024! Last night’s ceremony, held at the National Motorcycle Museum in Birmingham, was a chance to reflect on the achievements and advancements made within the UK composites sector in the last year. The Technology Behind the Award Traditional mold design…

-

AI and Digitisation in Composite Manufacturing

Composite manufacturing is ever evolving, and therefore the need for efficiency and precision are critical. Industries such as aerospace, automotive, and marine rely on composite materials to drive innovation, improve performance, and reduce weight. Yet, despite its importance, the composite tooling industry has long struggled with inefficiencies, primarily due to time-consuming manual processes. Plyable is…

-

Plyable’s Experience at CAMX 2024 and the Future of Composite Manufacturing

Last week, the Plyable team attended CAMX 2024 in San Diego, and it was bigger and better than ever. With a focus on the future of composite manufacturing and the role of AI, the event offered insights into where the industry is heading. Here’s a recap of our experience, the highlights from the event, and…

-

Transforming Marine Mold Manufacturing

The marine manufacturing industry is in a constant state of evolution, particularly in the high-paced world of marine racing. In this competitive environment, precision, durability, efficiency, and cost are critical factors that can make or break a team’s success. Plyable has been at the forefront of this industry for years, helping teams achieve their goals…

-

Advancing Diversity in Aerospace through Innovation and Inclusion

Last month, Plyable exhibited at Farnborough International Airshow. Alongside the opportunity to meet and network with industry leaders, Plyable also had the chance to take to the stage. Sales Director, Elaine Winchester, joined a very engaging panel on diversity and inclusion within the aerospace sector and what can be done to address the imbalance. The…

-

Everything You May Have Missed at Farnborough International Airshow 2024

The Farnborough International Airshow (FIA) 2024 was, once again, a fantastic event, bringing together leaders and innovators from across the aerospace industry. This year’s show featured cutting-edge technology, groundbreaking announcements, and global delegations, all focused on the future of aerospace. Here’s a recap of everything you may have missed, including highlights from Plyable! Component Parts…