Automated Mold Design

At Plyable, we always strive to be at the forefront of innovation within manufacturing and mold design.

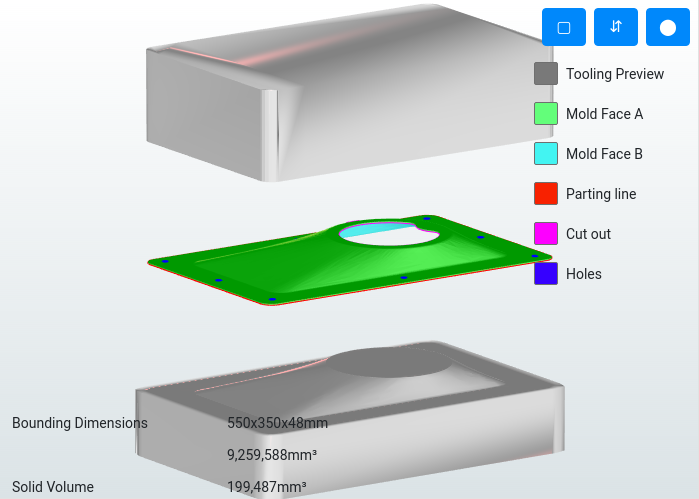

We’re disrupting the norm with our automated mold design process - a unique solution in the market. Traditionally, mold design could be laborious and time-consuming. Plyable’s system computes pull directions, automatically extrudes a shape’s boundary and adds elements such as laser targeting holes, to generate a precise STEP file of the mold. The process is 100% computer-driven, producing supplier-ready files in a matter of minutes.

While our focus is on carbon fibre parts, we’re actively working towards expanding compatibility to include more materials and multiple molds.

Plyable is pushing boundaries in the future of mold design, delivering unprecedented efficiency and using innovative systems such as our automated mold design, to significantly reduce lead times. Speak to the team to find out more.