Author: Adam

-

Plyable at CAMX 2023: Empowering Next-Gen Manufacturing

The countdown to CAMX 2023, North America’s premier composites and advanced materials event, has begun! Plyable is thrilled to announce our participation in a thought-provoking panel discussion at this year’s conference in Atlanta, taking place from 30th October to 2nd November. We’re going to give you a sneak peek into what you can expect from…

-

Plyable nominated for JEC Composites Startup Booster Award

Plyable are delighted to share that we have been nominated for The 2023 JEC Composites Startup Booster Award! The JEC Composites Startup Booster Award is the leading startup competition in the world of Composites and Advanced Materials. Launched in 2017, Startup Booster has been organized in three different regions (Europe, USA and Asia) and has…

-

Plyable Feature Update – Banana For Scale

Playble has launched a new DFM update that allows you to see the scale of your mold compared to a banana. Why a banana? – why not!

-

What is Epoxy Tooling Board?

Tooling Board, sometimes referred to as Modelling Board, is a material used mostly for making prototype or low-run patterns and mould tools for composite parts. Most of these boards fall into one of two categories, epoxy and polyurethane. Structurally, Epoxy Tooling Board is made from glass microspheres, epoxy resins and other chemical hardeners. The microscopic…

-

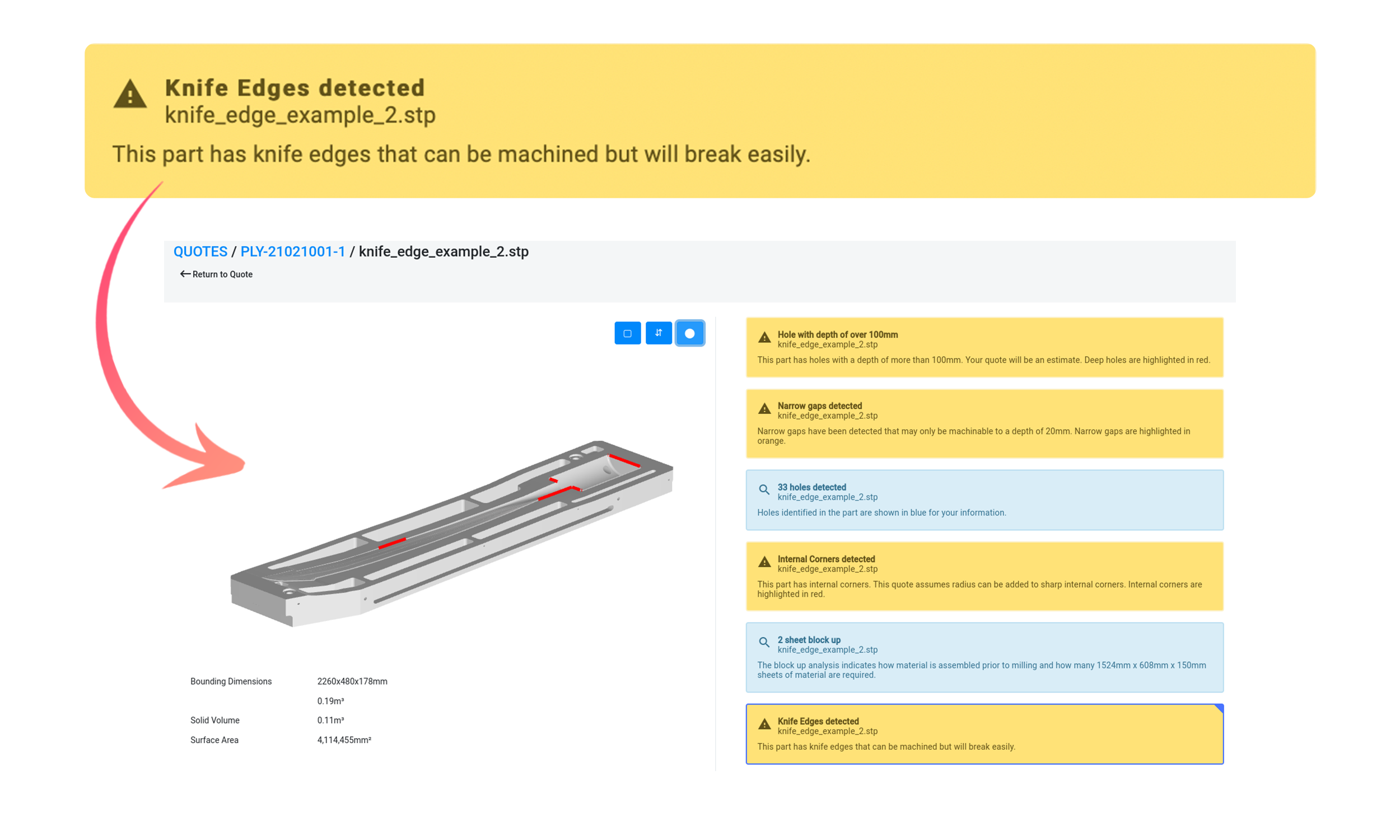

Plyable Feature Update – Knife Edge Detection

Playble has launched a new DFM update that will detect sharp features on molds. It will detect areas that are likely to break easily during production. This update will not produce an estimated price if a ‘Knife Edge’ is detected.

-

Plyable secures $3.2M investment to deliver their lightweight custom composite marketplace on a global scale

Plyable, award-winning, market-leading composite mold producer has now received a total of $4.25M investment to fund the growth of its time and significant cost-saving composite tooling solution. The demand for composites is growing exponentially, with the incredible, rapid innovation seen in aerospace, electric vehicle and marine industries. Award winning, market-leading disruptor in composite tooling, Plyable’s…

-

Plyable ISO9001 recertification

Plyable has ISO9001 recertification, highlighting the company’s commitment to the highest quality standards for its supplier and customer network. ISO 9001:2015 is a globally recognised quality management standard developed and published by the International Organization for Standardization (ISO). It provides a model that companies can use to build an effective quality management system. The standard…

-

Student Racing Partnerships – Customer Story

We’re delighted to announce that Plyable has recently teamed up with (OBR) Oxford Brookes Racing & (BR) Brunel Racing, two fantastic student racing teams! Both teams will be taking part in Formula Student which is Europe’s most established educational engineering competition, an international race series run by the Institution of Mechanical Engineers (IMechE), backed by…

-

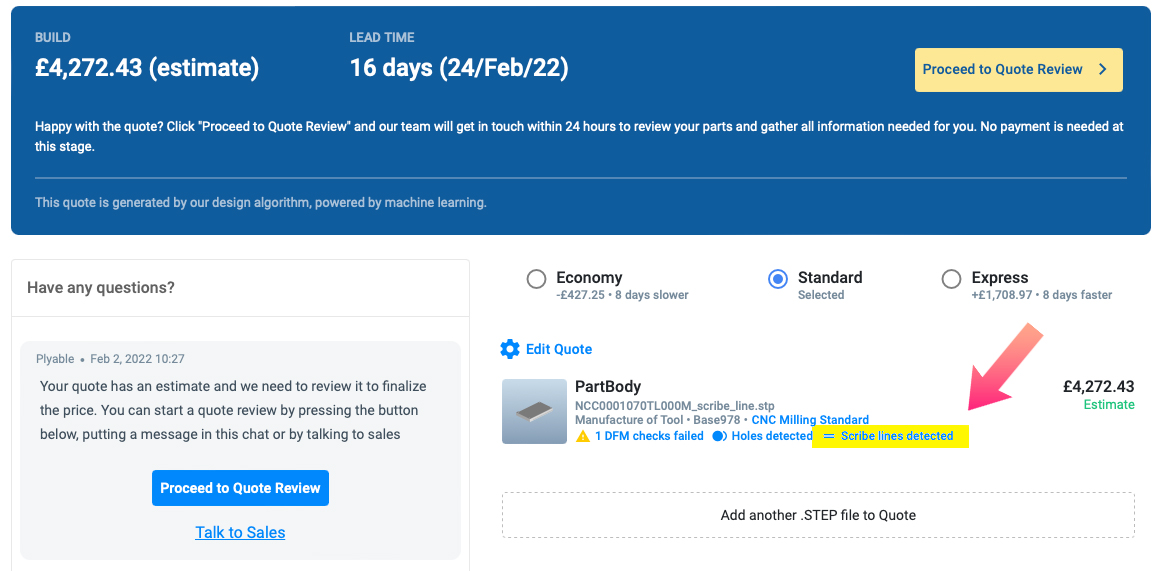

Plyable Feature Update February 2022

We’re focused on making the tooling experience even smoother that’s why we’ve deployed an update to the site that adds scribe line detection to parts. Scribe lines are impressions machined into mold tools such as curves, cross-hairs or letters and numbers. These impressions leave a resin mark on the component when it comes out of…

-

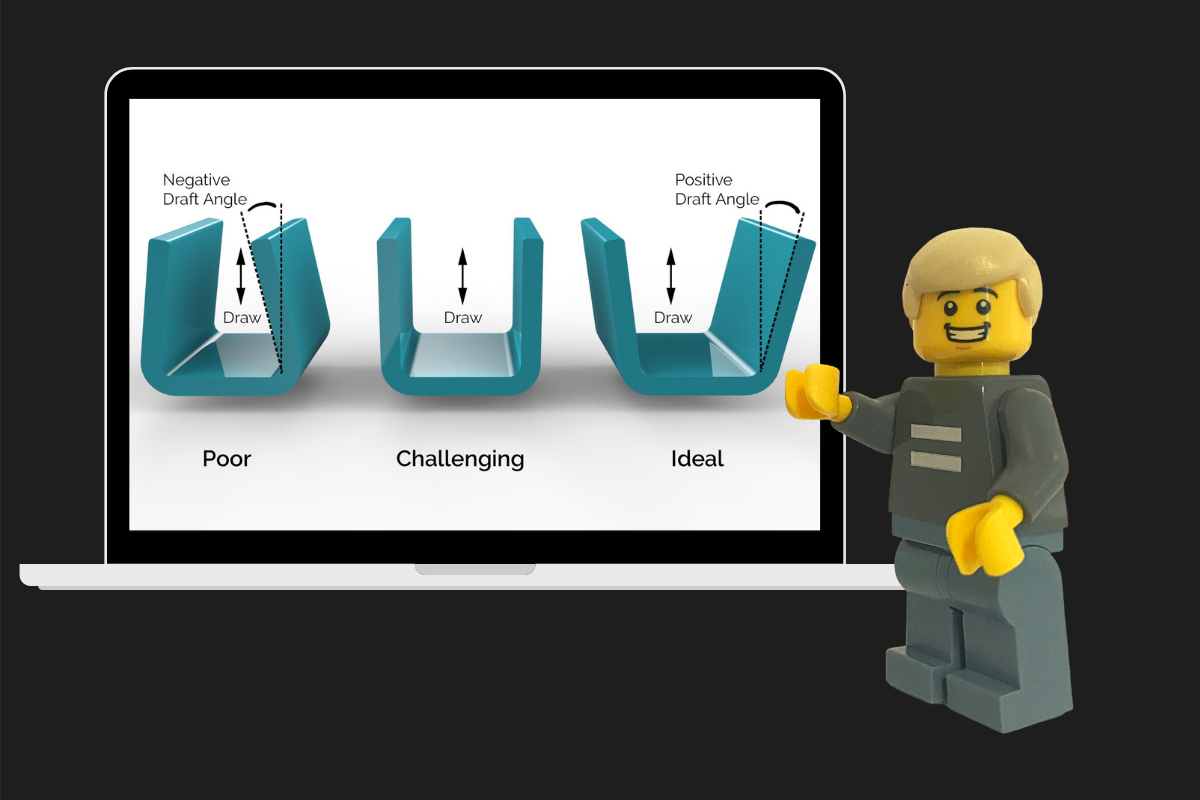

Tooling Essentials – Draft Angles

Tooling Essentials with Plyable Engineer Andy Haines Welcome to our first Tooling Essentials! Whether it’s new to you or a swift refresher, these are just a few of the important considerations required when designing the perfect tool for your part. Today we begin with Draft Angles. The geometry of your part needs to allow it…