Meet our leadership team

Our team are renowned for their expertise in composites manufacturing and SaaS capabilities. With backgrounds in aerospace, manufacturing, technology and engineering we bring the acumen, forward thinking and dynamic skillset to help our clients achieve more out of manufacturing.

Mark Runciman

CEO

Mark is a highly commercial Senior Business Leader with experience at the CEO and Managing Director levels.

Lisa Davis

CFO

Lisa is a Big 4 Qualified Chartered Accountant with 15 years experience as CFO of SaaS businesses.

Lisa has held a number of senior finance roles with companies whose turnover ranged from £1m to in excess of £100m.

Luke Hunter

CTO

Luke joined Plyable in 2019 as the founding engineer and became CTO in 2023. He has expanded the company’s software platform, led the development of Tangible, and delivered highly profitable integration projects with software partners.

Jamie Snudden

Sales Director

With more than 15 years of experience in composite manufacturing across multiple sectors and with a PHD in Aerospace Engineering, Jamie offers a wealth of knowledge, passion, and fresh ideas.

Change makes way for opportunity and growth

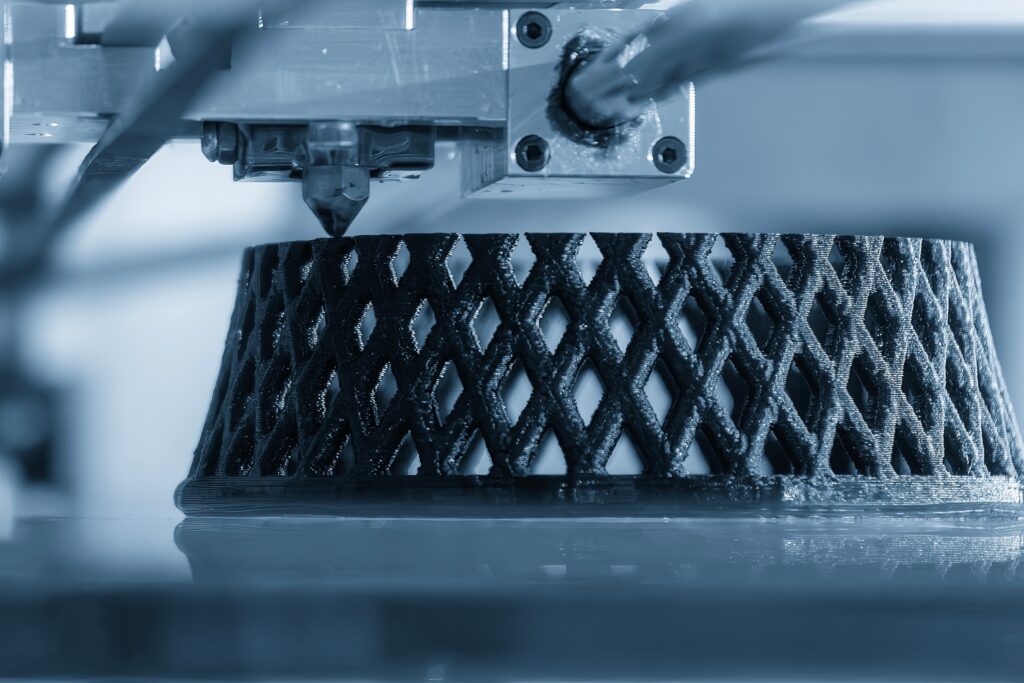

Composite based materials have been used to create structures and everyday products for a number of years however; it wasn’t until the 1930’s with the introduction of fiberglass, and then the subsequent development of fibre-reinforced polymers (FRPs) during World War II, that the composites industry begun to take shape.

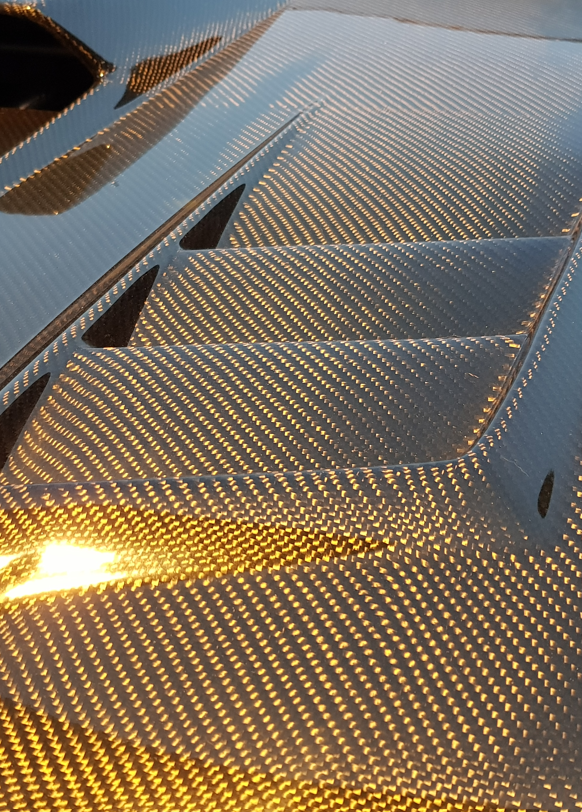

In previous years the composite industry was described as ‘cottage style’ with initiatives that we led by craftsman with expertise in creating the most intricate tools, vehicle parts, consumer goods and children’s toys. These niche materials offered an alternative to more established manufacturing sectors like metallics and plastics. Accelerated by the need for speed, efficiency and aerodynamics in markets such as Aerospace, Automotive and Marine the composite manufacturing industry has developed rapidly during the 20th and 21st century. In fact, the sector is now an established $182 billion dollars world-wide market comprising 42 000 companies worldwide 3 million employees globally. Last year saw a growth rate of 3.14% which reflects the industry’s ongoing expansion.

Backed by the likes of Aston Martin, BMW, McLaren, Boeing and Airbus composite manufacturing has been given a significant opportunity to drive innovation and strategy for our every day environments across a multitude of industries.

Seven years ago, Plyable saw a gap in the market; a need for an end-to-end comprehensive online manufacturing journey to not only link clients with a global supply chain, but to also use technology as a tool to speed up the lengthy and often slow design to manufacture process. Our software has introduced instant-quotes, auto-generated molding and risk alerts to offer a ‘fast to market’ approach to our clients.

We provide a supportive, consultative and professional experience underpinned by our custom built machine-learning manufacturing platform to aid the process of bringing composite molds and parts to life seamlessly.

Our mission

To offer a digital manufacturing revolution to the composite world through our seamless, customisable turnkey solution – driven by leading engineers, backed by technology and partnership.

”Everything was easy and straight-forward.

– US Aerospace client

Time to deliver was outstanding.”

Composite Manufacturing today

In today’s world 50% of the The Boeing 787 airframe is made from carbon fibre reinformed plastic. It’s lighter fuselage and wings contributes to around 20% fuel savings as the plane becomes 20% lighter than older planes. This move has helped Boeing manage it’s operational cost and move the company further forward in meeting its sustainability objectives. Compared to traditional materials like aluminium, these alternative materials reduce maintenance and fatigue in addition to supporting weight reduction. Find out more.

In the automotive sector, 1984 saw the first motorsport vehicle built with predominantly composite based materials. The renowned Ferrari GTO was one of the first ever cars to make widespread use of kevlar and carbon fibre. At 1160 kg dry weight, it was extraordinarily lightweight for a V8 turbo-powered supercar, after all the the goal was to deliver lightness with strength derived from the chassis and subframes, which is a method still used in todays racing team cars. Find out more.

A brief history of Plyable

2024 – 2025

Appointed by investors in 2024, Mark Runciman steps in as Plyable CEO to take Plyable to new heights. Mark employs a new leadership team to further streamline Plyable’s operational processes and strategy. Technology is placed at the heart of the business and as ideas evolve the team recognises the need to re-position as a leading edge consultancy supported by Tech. The tech arm of the business undergoes further development to be relaunched in 2026. The business also secures a technology patent on their new automated-molding feature.

The team attend a number of key events such as Farnborough Airshow and JEC World where they continue to gain exposure and leads with Tier 1 clients. Areospace and Automotive manufacturing markets become a defining client base for the company, followed by Consumer Goods and Marine,

In an industry where innovation and efficiency matter most, Plyable stands out as leaders in composite manufacturing. We’ve revolutionized the production of high-quality, cost-effective composite tooling. Now, we’re ready to redefine industry standards again by expanding into composite parts production. This strategic move aims to offer a complete, end-to-end solution that streamlines the manufacturing process, reduces lead times, and gives engineers and manufacturers worldwide more control over the entire production process.

2022 – 2023

A group led by Maven Capital Partners invests £2.5m into Plyable to support growth. Investment Director Alexander Sleigh says ”The Company has grown strongly in recent years with little external investment, and we are impressed with what the team have achieved to date with the business now a trusted supplier to many tier 1 manufacturers. Maven’s investment will provide Plyable with the capital it requires to accelerate growth and fulfil its potential.”.

The team continue to push the boundaries of composite manufacturing technology, introducing key features such as a DFM update that will detect sharp features on molds that are likely to break easily during production. The business also takes part in a British Standards audit, securing an updated BSI9001 certification. The team attend a number of key events such as JEC and Goodwood Festival where they gain exposure and leads with Tier 1 clients.

2019 – 2021

The Plyable team doubles in size between 2018 and 2019 and win Business Start Up Of The Year at the Composites UK 2019 awards dinner. One of Plyable’s investors, Syensqo, instructs their design team to engage with Plyable for design engineering consultancy – Syensqo have since become a long-standing client of Plyable. The company onboarded a number of high performing businesses and and starts to accelerate the technologies usage and output. Clients are attracted to Plyable’s unique position that brings together a specialised, approved supply chain that can support at a global level.

In 2019 we also received £500k in pre-seed investment from Forward Partners who recognised the innovative capability that our offering brings to many established manufacturing industries whilst in 2021 we received a convertible note from The Boeing HorizonX Global Ventures accelerator programme.

2018

The company was founded in Oxford by Martin Oughton and Adam Lofts. Work began to develop and technology solution to serve the composite manufacturing market and speed up the design to manufacture process. The business was initially called Mouldbox, but was soon changed to Plyable to better reflect the company’s strategic focus on building the future for composites manufacturing.

During this time we were given a £100k grant by Innovate UK which we utilised to grow the team and secure the in-house capability needed to transform Plyable into a commercial business. Learn more

Why use Plyable?

We recognise the critical role technology plays in shaping a sustainable, long-term solution future for manufacturing.

We strengthen your manufacturing approach by enhancing your capability

Our technology opens doors to find innovative methodologies and materials in our supply chain. When new developments arrive in the composite industry we ensure your team is in first place for production opportunities.

While we’ve built a strong reputation for our composite molds, and our supply chain is equally capable of producing composite parts. Recognising this untapped potential, and driven by our customers’ needs we now offer both composite mold and part production. Our desire is to provide clients with more continuity and control throughout the manufacturing process and allow seamless interactions between our service delivery, offering and technology.

Plyable offers a streamlined service that reduces lead times, enhances overall quality and increases longevity of its final products. This holistic approach ensures that customers receive the best possible service at every stage of their journey.

We offer you the ability to scale without the risk, through utilising our global supply chain

Our vetted and approved supply chain work to a minimum ISO 9001 standard. We work closely with our suppliers to ensure price, product quality and customer service matches our brand and future ambitions.

Thinking of scaling your business or enterprise? Our approach allows for you to take on more work and find opportunities that you wouldn’t otherwise be aware of. You can also use our software’s ability to connect with other manufacturers creatively. Curate new strategies, such as diversification of products, to enhance your existing offering,

We offer your team opportunities to stay ahead in an ever-evolving marketplace

We understand the unique challenges around innovation, R&D and sustainability so we’ve built our technology around finding ways to improve these areas of manufacturing with composite’s parts and tools at the heart of our offering.

Because our software embodies so much versatility and skill in the composite market we regularly come across clients seeking newer, evermore flexible materials, and a pursuit of the best design feasibilities out there. We understand the constant need to authentically evolve to sustain market interest and demand and our in-house team have the capabilities to help transform ideas into real life product.

A streamlined global solution for engineering, technology and supply chain…

Advanced expertise on hand to support you from ideation through to delivery

”We provide clients with a supportive, consultative and professional experience underpinned by our unique technology-driven platform built specifically to bring composite molds and parts to life seamlessly.”

Alan Purves – Technical Director at Plyable

At Plyable we are more than just a design to manufacture consultancy. Our team project engineering team works together with our technology to enable engineers around the world to gain the ability to refine strategies, plan projects, find solutions to major design challenges and manage capacity levels. With a combined 70 years experience in the composite engineering and manufacturing our team is here to help at every stage of the journey.

A tech-led solution for now and far into the future.

Our technology has been built with the customer at the heart of the design. We’ve considered every step on the route to manufacture and we will continue to evolve as part of our strategy

Plyable’s Approved Partners – the heartbeat of our software.

Our verified international supplier network enables Plyable to respond to our customer’s global needs. To enable clients to access client briefs for the purpose of quoting a tool or part design, partners require Plyable to approve and then integrate them into the portal.

Before onboarding occurs we carry out a full physical workshop audit and research partners’ accreditations (all suppliers need to be accredited to a minimum BSI IS09001 standard), check they can demonstrate superior product quality and give insight into price points and financial status. Suppliers graded A or B, our ‘approved pass rate’ can enter our system. All suppliers are required to sign NDA’s and client identification data is anonymised within files so data remains private.

Our manufacturing sectors

Aerospace

Reach for the stars with our manufacturing solution for planes, space craft & eVTOL

Marine

Accelerating manufacturing in the motorsport, luxury and passenger car space

Built Environment

Enrich construction with quality products that support faster build rates and improved sustainability

Consumer Goods

Create meaningful solutions at record speed for consumers to both value quality and enjoy

Other Sectors…

Our manufacturing tool can help with composite manufacturing for all types of uses

”One plus one equals three”

The world of composites offers creators a wider playing field than ever before. To support our ever-evolving landscape it is the design engineers role to consider the power that comes with combining two or more useful materials together. This magical impact creates a product that is more than the sum of it’s parts; a unique workable part or mold in our very consumer-driven world.

The purpose of our solution is to offer an unrivalled service backed by niche technology to enable clients can achieve results faster, with more flexibility, capability and sustainably than ever before.

We’ve built the world’s only AI-driven manufacturing software for the engineering and production of composite and metallic molds and parts.

‘’Like Amazon, for Composites – Composites World’’

Our manufacturing software delivers a FAST and INSTANT quotation with ZERO upfront commitment. Only pay when placing your order.

Bank Grade Security

Wordwide Delivery

Stay connected.

Follow us on LinkedIn or sign up to our marketing newsletter.

- See our latest projects first

- Connect with our expert team

- Access deals and promotions

”Great communication, the website was very good and allowed easy sharing of files & communication.

The team were a great help and ultimately designed us a fantastic tool”

-Automotive client, July 2025