Dates: Nov 2020 – Present Day

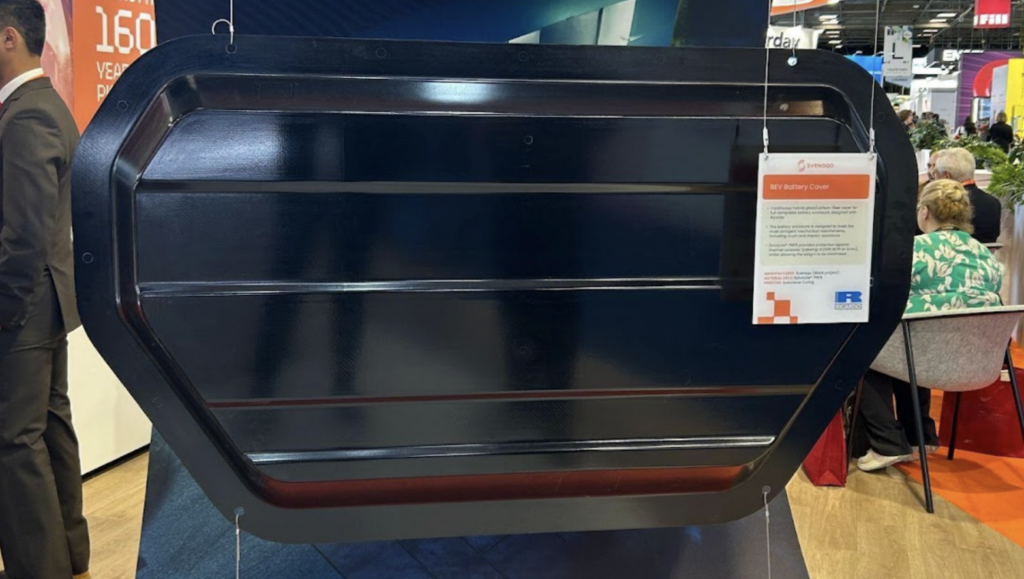

In a recent collaboration with leading materials supplier Syensqo, Plyable demonstrated its ability to deliver rapid and reliable tooling solutions, supporting advanced development projects focused on composite manufacturing.

Client Name: Syensqo

Challenge/Opportunity:

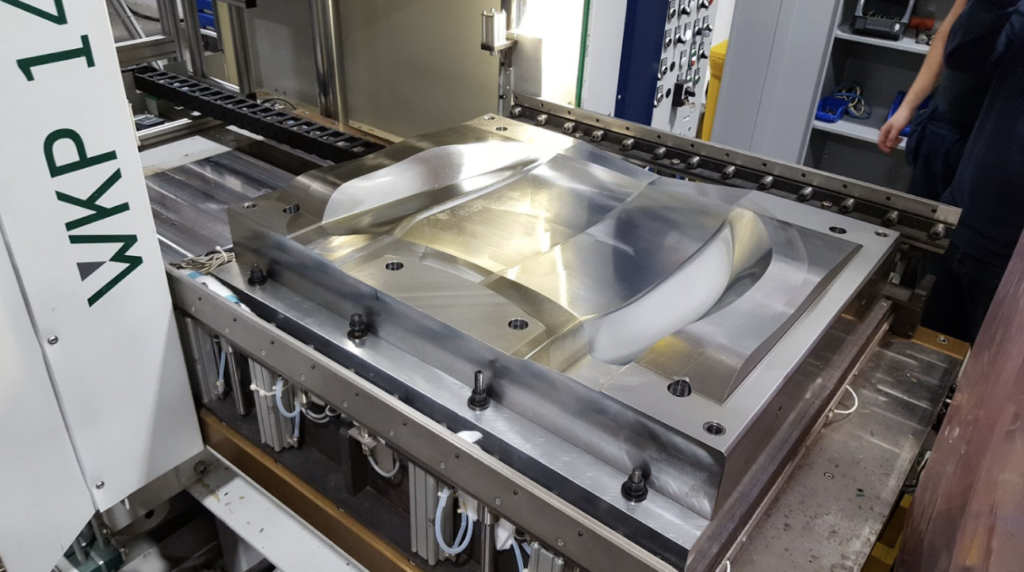

Plyable began working with Syensqo’s Customer Engineering department in November 2020. As materials specialists, their focus is on reducing cure times in carbon fibre composite manufacturing without compromising the material properties. As such, there was a significant emphasis on hot compression mould technology. They required various backed hot metal press mould tools to support their materials testing and development processes. The primary challenge for Plyable was to design and manufacture these mould tools quickly while maintaining the same consistent high-quality standards.

Solution:

Plyable took on the project management responsibilities of mould design and production, ensuring clear communication with stakeholders and seamless coordination with multiple suppliers. Leveraging our in-house design capabilities and global supplier network, Plyable has been successfully delivering tools to the Syensqo customer engineering team since 2020.

Key Results:

- 44% faster lead time in tool manufacturing

- High-precision tools that meet exacting standards

- Trust in Plyable’s supplier network, leading to consistent reorders for diverse projects

Value Added:

Plyable’s in-house design capabilities, coupled with our global supplier network, enabled the Syensqo customer engineering department to rapidly iterate and test their materials. By consolidating the design and manufacturing processes, Plyable saved Syensqo valuable time in their development project cycle, allowing them to focus on their objectives. Plyable’s vetted supplier network ensured that Syensqo could confidently place a diverse range of projects with us, knowing that even with a different set of suppliers, the results would meet the same exacting standards.

“Our collaboration with the Syensqo’s customer engineering department highlights Plyable’s ability to deliver high-quality tools quickly and efficiently, even for complex and varied projects. Our advanced technology and reliable supplier network ensure our customers can trust us for a diverse range of tooling needs. This project demonstrates our dedication to making composite mould manufacturing easier and faster for everyone involved.”

Jamie Rankin, Project Engineer at Plyable

“Syensqo’s Application Center, Heanor UK, has been developed to co-innovate with our customers in state-of-the-art composite manufacturing. The ability to be agile and adaptable to meet our customer’s unmet needs is vital. By working with Plyable, we have significantly reduced our tooling lead times, meaning we can be faster and more flexible in the development of new material and processes. We now have a reliable partner who is our first point of contact for all our tooling needs.”

John Hackett, Senior Engineer at Syensqo

Plyable fully supported these projects by leveraging our global supplier network, working in parallel to meet and exceed expectations. The short project timelines and high precision requirements demonstrate Plyable’s commitment to pushing industry boundaries and delivering unmatched value.