Plyable’s Expansion into Composite Parts Production

In an industry where innovation and efficiency matter most, Plyable stands out as leaders in composite manufacturing. We’ve revolutionized the production of high-quality, cost-effective composite tooling. Now, we’re ready to redefine industry standards again by expanding into composite parts production. This strategic move aims to offer a complete, end-to-end solution that streamlines the manufacturing process, reduces lead times, and gives engineers and manufacturers worldwide more control over the entire production process.

Plyable’s Origin

Plyable started with a vision to transform the composite manufacturing industry using cutting-edge technology and innovative processes. For the past six years, we’ve provided high-quality tooling to customers worldwide, using our extensive supplier network to cut lead times by 44%. This efficiency is the key to allowing us to meet the needs of our clients across various industries, from aerospace and defence, to automotive to marine.

Expanding Capabilities: From Molds to Parts

While we’ve built a strong reputation for our composite molds, our supply chain is equally capable of producing composite parts. Recognizing this untapped potential, we’ve decided to expand our offerings to include composite parts production. This decision is driven by our customers’ needs and our desire to provide them with more continuity and control throughout the manufacturing process.

Engineers and manufacturers require high-quality composite parts to complete their projects efficiently. By manufacturing both the moulds and the parts, Plyable can offer a more streamlined process that not only reduces lead times but also enhances the overall quality and reliability of the final products. This holistic approach ensures that customers receive the best possible service, from initial design to final delivery.

Leveraging Advanced Technology for Excellent Results

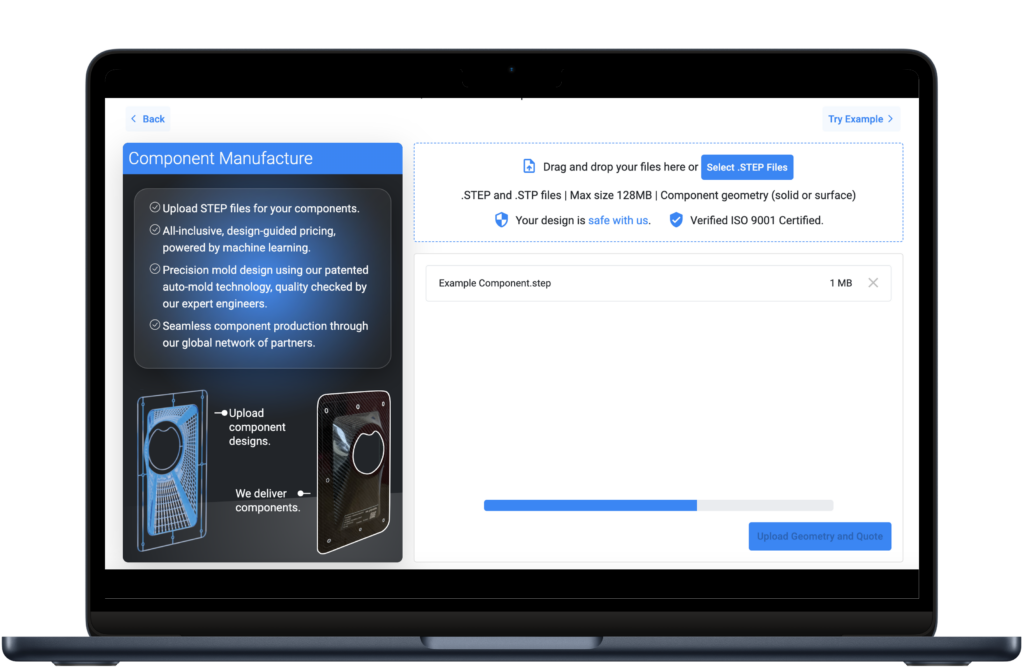

Our expansion into composite parts production is driven by our desire to leverage advanced technology. Plyable’s AI-driven platform, which has successfully provided quick quotes and lead time estimates for tooling, can now extend these capabilities to composite parts. This innovation allows customers to get accurate quotes rapidly, helping them budget more effectively and keep their projects on schedule.

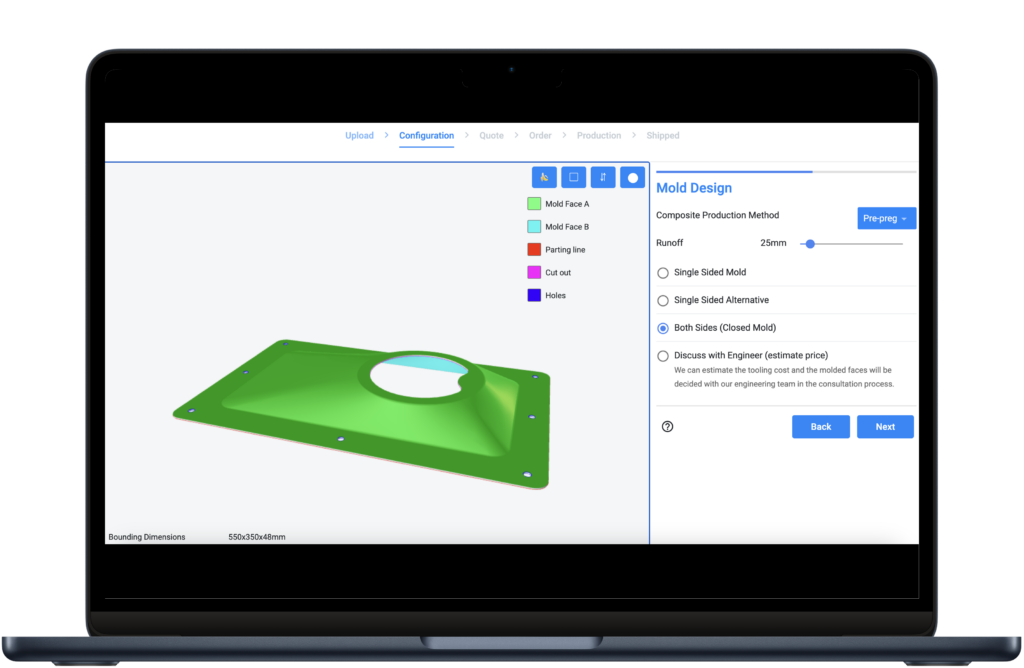

The platform’s ability to automatically generate mold designs through computer vision and machine learning significantly streamlines the production process. This technology ensures that every part produced meets high standards of precision and quality, reinforcing our reputation for high-quality composite manufacturing.

Addressing Industry Needs

The decision to add composite parts production to our capabilities is about responding to industry needs. In today’s fast-paced manufacturing environment, resources are often stretched thin, and efficiency is crucial. Our comprehensive solution addresses these challenges by providing a reliable, cost-effective, and time-efficient manufacturing process.

Our customers have consistently driven Plyable’s product development. Expanding into composite parts production is a direct response to customer demand for a more integrated and streamlined manufacturing process. This customer-centric approach underscores our commitment to delivering solutions that truly make a difference in the industry.

How Our Tech Comes In

Our automated mold design technology plays a crucial role in enhancing the efficiency and precision of composite parts manufacturing. Using advanced computer vision and machine learning, our platform can automatically generate optimal mold designs from our customers component files. This process significantly reduces the engineer time traditionally required for mold design, and ensures consistency and accuracy.

As a result, engineers can quickly move from the design phase to production, with quick quotes and precise lead time estimates. The seamless integration of automated mold design into the composite parts manufacturing process not only accelerates production timelines but also gives customers greater control and reliability, ensuring high-quality outcomes every time.

Enhancing Supply Chain Continuity and Reliability

One of the major benefits of our expansion is the enhanced continuity and reliability it brings to the supply chain. By managing both the production of molds and the parts, we ensure a seamless transition between these critical stages of the manufacturing process. This reduces the need for multiple suppliers, minimizes shipping requirements, and creates a more efficient operation overall.

Driving Innovation and Setting New Standards

Innovation has always been at the heart of what we do at Plyable. Expanding into composite parts production shows our dedication to pushing the boundaries of what’s possible in composite manufacturing. By leveraging cutting-edge technology and continuously improving our processes, we set new standards for efficiency, quality, and customer satisfaction in the industry.

Our ability to now offer a complete, end-to-end solution, from mold design to part production, positions us as true industry leaders. This comprehensive approach not only meets the immediate needs of our customers but also anticipates future demands for the industry.

Our expansion into composite parts production marks a significant milestone in Plyable’s journey. By providing a seamless, integrated solution and a robust supply chain, we are set to transform the composite manufacturing landscape. This move not only addresses current market requirements but also sets a standard in delivering comprehensive, efficient, and reliable manufacturing solutions.

As we continue to innovate and expand our capabilities, our customers can look forward to even greater efficiency, reduced lead times, and enhanced control over their manufacturing processes. With a commitment to excellence and a customer-centric approach, Plyable is a trusted partner for engineers and manufacturers worldwide.

For more information about Plyable’s new composite parts production and how it can benefit your projects, get in touch with the Plyable team.