Composite parts are made by layering composite material onto one or more molds. Getting the mold design and manufacture right is crucial to a good end result. With Plyable all you need to do is upload a part design and with a click you will receive a mold ready for lay-up of composite material.

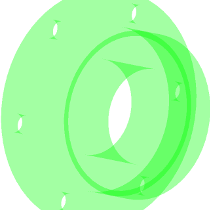

1. Design the part

2. Online mold design

Plyable technology simulates the manufacturing process in real-time

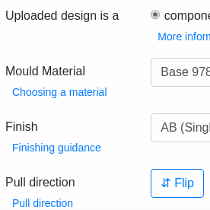

3. Instant online quote

Plyable will provide you with the cost and lead time to manufacture the mold

4. Manufacture

Plyable manufacture the mold using CNC or 3D printing processes

5. Finishing

The mold is sealed and releasing agent is applied by Plyable

6. Delivery

Track the order as it is processed and delivered

7. Material lay-up

You receive the mold ready to lay up composite material